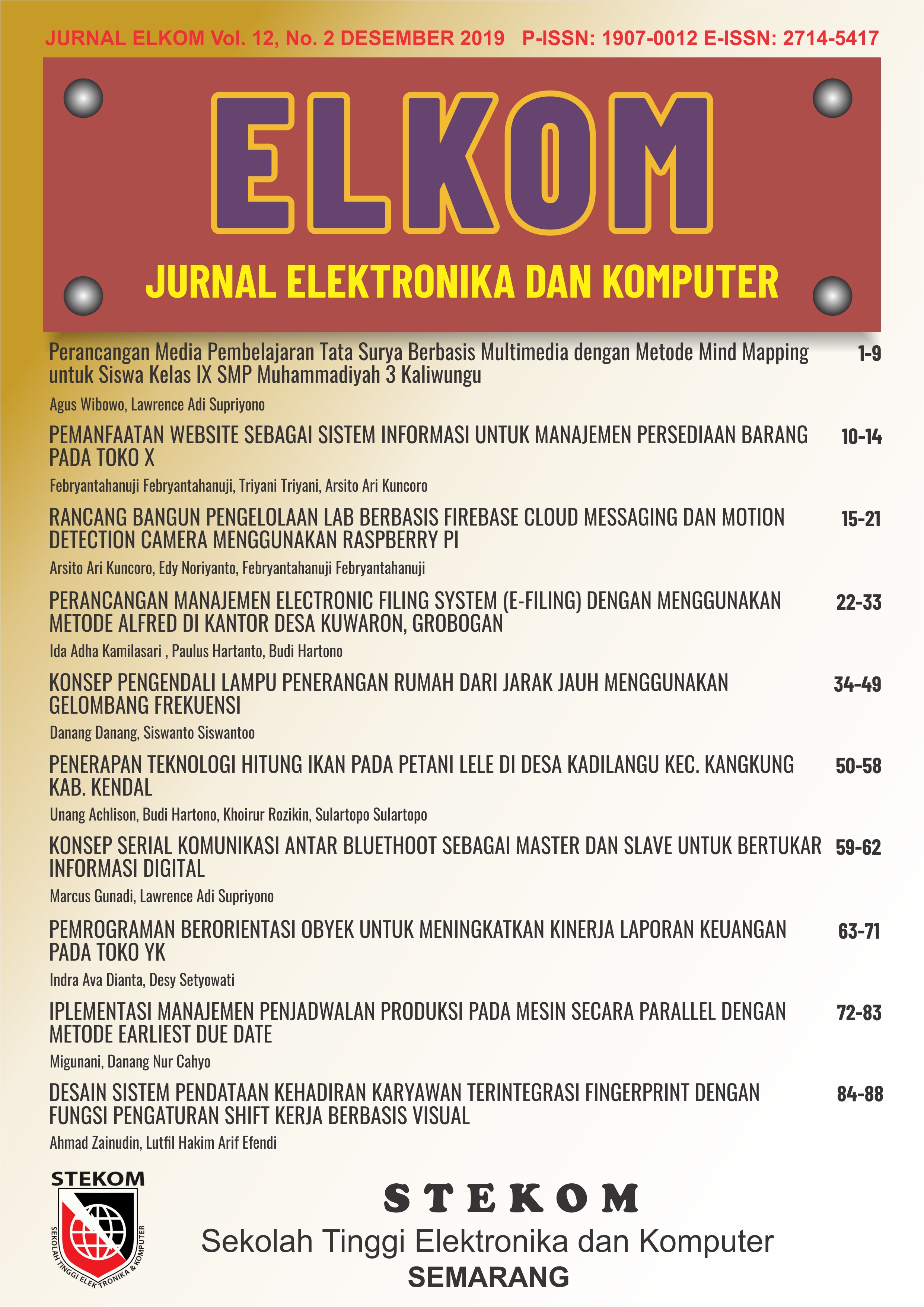

IPLEMENTASI MANAJEMEN PENJADWALAN PRODUKSI PADA MESIN SECARA PARALEL DENGAN METODE EARLIEST DUE DATE

DOI:

https://doi.org/10.51903/elkom.v12i2.173Keywords:

Information Systems, Management, Scheduling, Production, Earliest Due DateAbstract

The management of production and operations in factory machinery is an optimal management effort in the use of resources consisting of labor, machinery, equipment and raw materials. The production and operations manager directs various inputs in order to produce various outputs or results in units of quantity, quality, price, specific time and location according to consumer demand. Efficiency and effectiveness of the production process to be achieved requires proper scheduling management so that the production output produced can be completed according to target. Management of production and customer orders is still simple, besides that the status of raw material inventories that cannot be directly known can often result in delays in the production process and even production cannot be done as soon as possible. Scheduling orders that enter using the system first in first out where the first order that comes is done, but has not considered the number of orders, priority of customers, maturity of workmanship and engine capacity so that the estimated completion of the order can not be known. To make it more efficient and directed, the Earliest Due Date method is used by sorting the production work based on the closest due date. This method can be used for scheduling on one machine or for scheduling on several machines (parallel machine) so that the scheduling management information system can manage effective production scheduling and produce production reports automatically as needed.